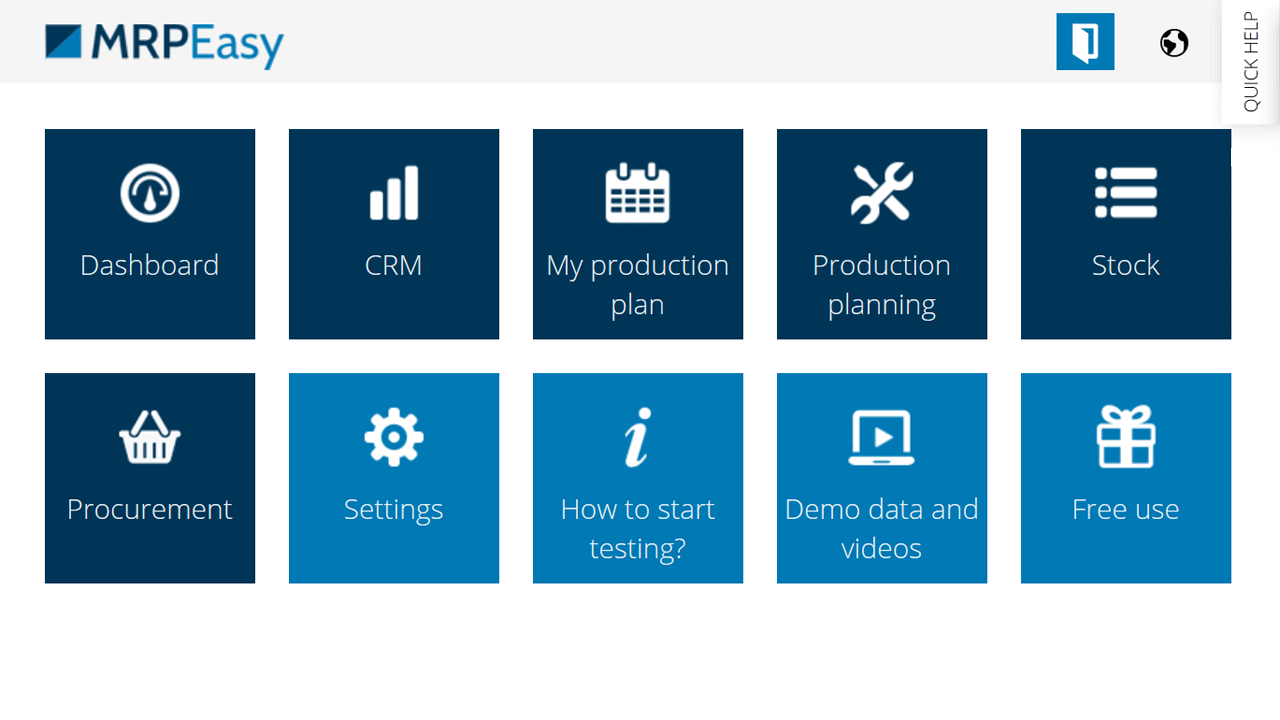

Manufacturing Software

A comprehensive manufacturing management system helps streamline multiple functions of your enterprise:

- Receiving Gain insights into shipments or material from suppliers that have been delivered, but that are not yet at their final location. Make sure items at low stock levels are staged and put away first, reducing the impact of out-of-stocks and inefficient fulfillment processes.

- Put-Away locate your entire inventory on your shelves. Guide your workers to the right location, set up their picks in the proper order to minimize travel time, and increase the number of orders they can pick each day.

- Packing Ensure the accuracy of each order that is picked and reduce material costs

- Delivery See that each order is properly packaged and delivered to the right destination and delivered on the right time and date.

.

Inventory

- Product Status (on hold / available / sale / order)

- Inventory Order summary

- Product returned

- Stock analysis( stock in and stock out)

- Damage products

- Processing stocks

Manufacturing process

- Analyze and monitor production record, costs and requirements for each sales order

- Manage production wastage to help increase revenue and ensure customer satisfaction

- Ensure job allocation or manage the workflow of productions

Supply chain management

Taking a view into sales data in real- time, inventory, delivery schedules, and more, you'll have a total view of what are coming in and what’s going out, and an easier time managing daily workload.

- Manage purchasing and receiving processes.

- Know what your customers want now, and plan for what they'll want next.

- Control inventory lean, and still address demand.

- Get the tools to make smarter buying decisions and to negotiate better terms.

- Help improve customer service and, therefore, customer relationships.